Kancheepuram Silk

The Kanchipuram silk sari is a type of silk sari made in the Kanchipuram region in Tamil Nadu, India. These saris are worn as bridal & special occasion saris by most women in Tamil Nadu, Kerala, Karnataka & Andhra Pradesh. It has been recognized as a Geographical indication by the Government of India in 2005–2006. As of 2008, an estimated 5,000 families were involved in sari production. There are 25 silk and cotton yarn industries and 60 dyeing units in the region.

Weaving The saris are woven from pure mulberry silk thread. The pure mulberry silk and the Zari used in the making of Kanchipuram saris comes from South India.To weave a Kanchipuram sari three shuttles are used. While the weaver works on the right side, his aide works on the left side shuttle. The border colour and design are usually quite different from the body. If the mundhi (the hanging end of the sari) has to be woven in a different shade, it is first separately woven and then delicately joined to the Sari. The part where the body meets the mundhi is often denoted by a zigzag line. In a genuine Kanchipuram Silk Sari, body and border are woven separately and then interlocked together. The joint is woven so strongly that even if the saris tears, the border will not detach. That differentiates the kanchivaram silk saris from the others.

Bhavani Jamakkalam

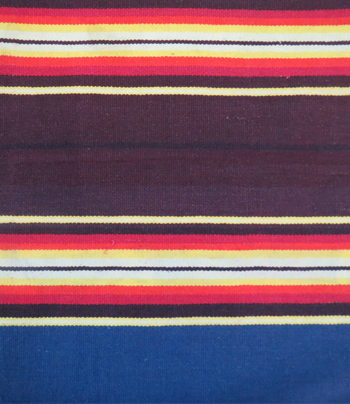

Bhavani Jamakkalam refers to blankets and carpets manufactured in Bhavani in Erode district, Tamil Nadu. It has been recognized as a Geographical indication by the Government of India in 2005-06.

History In the late nineteenth century, competition from British made textiles led Indian weavers to invent new types of garments. In Bhavani, a community of weavers called Jangamars weaved a type of blanket using colored coarse threads called Jamakkalam. The popularity of the product led to the production of jamakkalams by other weavers replacing the production of traditional sarees and other cloths.

Types Two types of jamakkalams are produced in Bhavani. The first type is made from coarser cotton threads capable of producing carpets with colored bands.As the thread was coarser, designs could not be weaved on to this type of carpet. Hence, a second softer variety of jamakkalams were introduced that were made of artificial silk threads enabling weavers to weave different kinds of border designs. Jamakkalams are also used to make fashion products such as backpacks..

Madurai Sungudi

Madurai Sungudi is Design of Madurai in the Indian state of Tamil Nadu, which is an exclusive textile product traditionally produced using tie and dye (using natural dyes) method by the Saurashtrians who migrated to Madurai under the patronage of King Thirumalai Naicker in the 17th century. The fabric's traditional popular use is as a saree; the fabric is now also used to make shirts, salwars, shawls, handbags, bed sheets and pillow cases. The product has been given protection under the GI registration act.

In recent years, in view of tough competition from other textile fabrics, to meet the market demand this fabric, "sungudi" as it is commonly known, is made with modern designs and techniques of block printing, wax printing and screen printing.

Arani Silk

Arani means a village made beautiful by rivers. In Tamil “Aru” means River and “Arani” means Beautification. Anyone who happens to travel to Arani would necessarily have to cross many rivers. This town is remembered mainly for the fine silk sarees produced here from time immemorial. In this regard, the Imperial Gazetteers of India Provincial series – Madras – II – Published in 1908, has stated that “A considerable industry in the manufacture of silk and cotton fabrics is carried on in the town (Arani)”. Dobby Variety Traditionally the silk sarees woven in Arani were called DOBBY variety. These sarees were woven by using DOBBY with single thread warp (yarn running horizontally) and single thread weft (yarn running vertically). The border has thin line of Zari (gold thread). The saree weighs about 300 grams.

Korvai Variety (One Side And Double Side) Anticipating customer's willingness for new designs, the technique of interlacing the body and border part of the saree, to give solid colour border which is known as contrast weaving (KORVAI) was introduced. The body and border of the saree has different colours. Again single warps were used for these sarees. The weight about 450 to 600 gms. This Korvai Border Saree is produced in one side or Double side of the silk sarees.

Self Border Variety Sarees woven either with one side or double side border, but without interlacing (korvai) the body and border is known as self border Saree. This may be woven either with single warp or double warp with single weft or multiples up to 3 strands. Proof of origin: (Historical records) Arani means a village made beautiful by rivers. In Tamil "Aru" means River and "Arani" means Beautification. Any one, who happens to travel to Arani would necessarily have to cross many rivers. This town is remembered mainly for the fine silk sarees produced here from time immemorial. In this regard, the Imperial Gazetteers of India Provincial series – Madras – II – Published in 1908, has stated that "A considerable industry in the manufacture of silk and cotton fabrics is carried on in the town (Arani)".

Kovaikora Cotton Sarees

Kovai Kora Cotton means cotton yarn saree, in which the kora silk for warp and 2/100 gas mercerized extra - long staple for weft and Jari for making pallu and putta, with intricate craftsmanship are used.Kovai Kora Cotton saree is a blend of cotton and silk yarns beautifully woven in the fine craftsmanship, unsurpassed in the annals of textile history The people of Devangar Community in the GI area are said to hail from Ahmed Nagar in Gujarat and migrated to South India as a result of the annihilation of Vijaya Nagar empire in the Talaikotta War in 1565, when the Kayatri Peetam of Devangars in Hemakooda Parvatham was destroyed. They settled at Sirumugai, Mettupalayam and Sathyamangalam of the then Coimbatore district. They are the pioneers of weaving Kovai Kora Cotton. Historians claimed that the name Deveangar means the weavers of the dresses used for clothing the celestial bodies. (Deva - God, Anga – body ). The practice of making available the attire for local satraps and chieftains had been in vogue at Coimbatore District.

Salem Silk known as Salem Venpattu

Salem Silk Textiles include the white silk dhothies, silk Angavastrams (upper cloth) and white silk shirtings. These white silk goods are traditionally used during marriages and other festivals as specialty items. They are produced from time immemorial by the local traditional weaving community called as "Sourashtra" Community. They live in large numbers in Salem Town and peri urban areas. In Tamil Nadu, Silk Sarees are generally produced in places like Kancheepuram, Thirubuvanam, Kumbakonam, Arni, etc. However, white silk textiles are unique only in Salem Region produced by the highly skilled weaving community in the area. The silk used in Salem White Silk goods is produced from Cross-Bred (CB) silk worm Cocoons which are either yellow or dull white in colour. For the warp the silk from these Cocoons is bleached, so that the silk yarn will be shining pure white in colour. The silk fibres from 7 – 8 silkworm Cocoons are reeled together to make it a strong fibre. This yarn is of 16 / 18D or 18 / 20D quality.Salem Silk Dhothy is well known for its White Variety with its lustre.

Thirubuvanam Silk Saree

Thirubuvanam is an ancient temple town associated with the making of aesthetic silk sarees, traditionally weighing around 450‐1250 gm. The silk weighs around 400 gm and the rest of the weight is constituted by the Zari, Conventionally these silk sarees would measure about 18ft. in length and 4ft in breadth with one sided border only. In practice, it takes almost 15 days to complete the creation of a saree, with finesse. These sarees are elaborately hand‐woven and contain intricate brocades and motifs which are well‐received. Silk is stronger than most natural fibers, and is comparable in strength to synthetic fibers such as nylon and polyester. Garments made form silk are light, but warm and absorbent. They have excellent draping qualities and have a natural resistance to creasing and wrinkling. Notably, this is the only society with an ISO Mark, which speaks volumes about the quality of the goods. Thirubuvanam Silk Saree are traditional wedding saree of pure silk and gold electro plated silver zari thread, medium weight with motifs, body and border woven in the same single warp. Thirubuvanam Silk Saree are made from the commonly domesticated silk worm of the Genus Bombyx which feeds on the leaves of the mulberry tree hence also called mulberry silk. The speciality of the Thirubuvanam silk saree is that using filature silk for both warp and weft resulting in high Quality, Shining, Uniformity and luster. The Society is using best skein of yarn and Gold‐electro plated Silver Zari. The silk dyed in the society owned dye house with ETP and ZLD facility itself and given to the weavers as per the design. The common designs of motifs used in Thirubuvanam are natural and floral like that Mango, Kalasam, Temple, Ruthratcham, Diamond, Neli and Kodi visiri. Border: Another speciality 'korvai' means solid or contrast borders with series of delicately woven in zari. The three bells denoting the chalangai or anklet could well be followed by the chequered pattern of the peacock's eye, the arm jewel – vanki, bunches of grapes, creepers and mangoes….. All in one saree and the touch of surprise – 'meena' work or coloured thread in between the zari. Colours: Revel in the plains the endless brightness of parrot green, the depth of coffee brown, the shimmer of golden yellow…… chose your moods. Or be surprised by the double coloured the blue – green mayilkazhuthu (peacock's neck), the red‐orange of a lion, the violet‐green of a new‐born mango leaf…Pallus: Elaborate end pieces woven separately and then skillfully woven together with the main body, without any signs of a joint… the wonder of pitni work. The Product includes the following a) Seer Mundhi Pure Silk Saree (Regular and Long) b) Attached Border (Korvai) Seer Mundhi Silk Saree c) Silk extra warp Design Silk Saree d) Plain Silk Saree e) Tissue Silk Saree f) Jangala Silk Saree g) Korvai Pattu Pavadai (Skirt) h) Ponnadai (Silk Shawls) i) Plain pieces

Kandangi Saree

Karaikudi is dry (owing to its tropical climate) and in contrast, the Kandangi sarees exude brilliant colours like bright yellow, orange, red and a minimal black in the traditional pattern of stripes or checks with broad borders woven in coarse cotton. Made out of natural dyes (generally vegetable dyes), the sarees give the Karaikudi feel of earthiness. The fine stripes and checks, horizontal and vertical, are made out of cotton yarn which is dyed into vibrant colours, the favourites being earthy hues of red, orange, brown and colours of chrome and mustard. With the changing time, more interesting colours have been introduced and these have managed to retain the vivacity of the Kandangi saree. These sarees are characterised by the large contrast borders and some of the sarees are known to have borders covering as far as two-thirds of the saree and the sarees are usually around 5.10 Meters – 5.60 Meters in length.

Source: Intellectual Property India